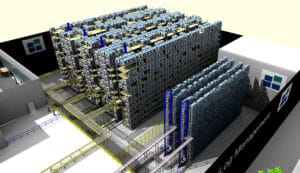

We plan your logistics virtually in 3D

With our 3D warehouse planning, we create tangible logistics solutions

Benefit from the advantages of virtual warehouse planning in 3D

Direct avoidance of planning errors, exact predictability of your investments

We rely on our three-dimensional planning and simulation tool for the planning of logistics facilities, logistics systems and logistics buildings. Within a very short time, true-to-scale logistics buildings and facilities can be recreated and material and goods flows simulated in real time.

Are you planning a new logistics building or do you want to optimise your logistics processes?

With our 3D warehouse planning, we visualise your logistics building according to your planning ideas and realistically depict warehouse technology, material and goods flows. Take a look at your new building even before it is realised.

By using our logistics simulation, we present concept variants to you in a tangible and comprehensible way. The performance and possible bottlenecks of the warehouse or logistics facility can be identified before realisation. High costs resulting from subsequent process corrections are thus avoided.

- Tangible

- Realistic

- Plannable

- Innovative

- Sustainable

- Future-proof

Avoid direct planning errors and high costs

We create your virtual logistics world

- With the use of VR technology

- Virtual warehouse tours with suppliers

- Virtual project and training rooms

- Virtual warehouse tour

- Opportunities

Business Cases — 3D Warehouse Models

- Logistics building with modern warehouse technology

- Use of automated guided vehicles (AGVs)

- Material flow simulation new logistics central warehouse

Our team of experts supports you

We are at your disposal in your conceptual design of logistics facilities, logistics systems or logistics buildings in every project phase.

- [1] Workshop

- [2] Data basis

- [3] Warehouse modelling

- [4] Presentation of results